ILC: The machine for the future

Reaching out our ambitions physics goals will be a major challenge. The International Linear Collider (ILC) will not only enable us to expand the frontiers of our knowledge of the universe; it is already challenging us to push boundaries in such diverse areas as advanced accelerator technology, materials engineering, and detector development. International teams of scientists and engineers are hard at work developing the design.

THE ILC TRAVEL GUIDE:

FOLLOW THE PARTICLES ON THEIR TRIP THROUGH THE ACCELERATOR

At the height of operation, bunches of electrons and their antiparticles (positrons) will collide roughly 7,000 times per second at a total collision energy of 250 GeV, creating a surge of new particles that are tracked and registered in the ILC’s detectors. Each bunch will contain 20 billion electrons or positrons – this means a very high rate of collisions. This high “luminosity”, when combined with the very precise interaction of two point-like colliding particles that annihilate each other, will allow the ILC to deliver a wealth of data to scientists that will allow the properties of particles, such as the recently discovered Higgs boson, to be measured precisely. It could also shed light on new areas of physics such as dark matter.

How will it work? How do the particles get from one end of the accelerator to the collision point at the centre, and what happens to them on their way? Here’s your travelguide.

1 SOURCE

Electrons are produced in the electron source. An intense laser beam shines onto a semiconductor cathode and knocks out billions of electrons. Electric and magnetic fields gather the electrons together and accelerate them to an initial energy of 5 GeV.

2 DAMPING RING

Their next port of call is the damping ring. The density of the particles in the bunch generated by the source is far too low, and the particles need to be packed into a much small volume – or damped – to reach the high ILC performance requirements. This is done in a closed storage ring accelerator similar to many synchrotron light sources around the world.

Indeed it is the same “synchrotron light” that the particles radiate as they go around the ring that causes them to pack together more tightly. But the ILC pushes this technology still further, demanding that the entire damping process happen in a fraction of a second before the bunches are extracted and sent on the next stage of their journey to the collision point. This requires some impressive technologies to make the particles radiate as fast as possible. No easy feat, but experiments at test accelerators have shown that these requirements can be met. Experts from the fields of light sources and high-energy-physics accelerators have worked together to create a design of a high-performance damping ring that will be up to the ILC job. One kind of special magnet, the so-called wiggler, sends the particle bunches on a serpentine course, causing them to shed some of their energy, which makes them more uniform within the bunch and thus reduces its size. Other technologies for the vacuum system needed to deal with the very high number of particles in the rings have also been the subject of intense study over the last several years.

There are two damping rings of three-kilometre circumference installed inside one tunnel – one for electrons, the other for positrons. When the electron or positron bunches leave their respective damping ring they will have gone around the rings about 20,000 times and become very compact and dense – but not quite dense enough. The bunches are still too long and need to be “compressed”, but that’s the next part of the story.

3 RING TO MAIN LINAC & BUNCH COMPRESSION

The neatly packaged and tiny – but still too long – electron and positron bunches are extracted from their respective damping rings and transported in opposite directions some 8 kilometres before being turned 180 degrees in a gentle arc of magnets, ready for the race back to the collision point. Before that all-important sprint through the main accelerator, the bunch length is compressed from 6 mm down to just 0.3 mm, using special sections of the same accelerator technology used in the main linacs, together with some special magnets. While doing this compression, the bunches undergo their first acceleration from 5 to 15 GeV. Now the ultra-compact bunches are ready to be accelerated to the collision energy.

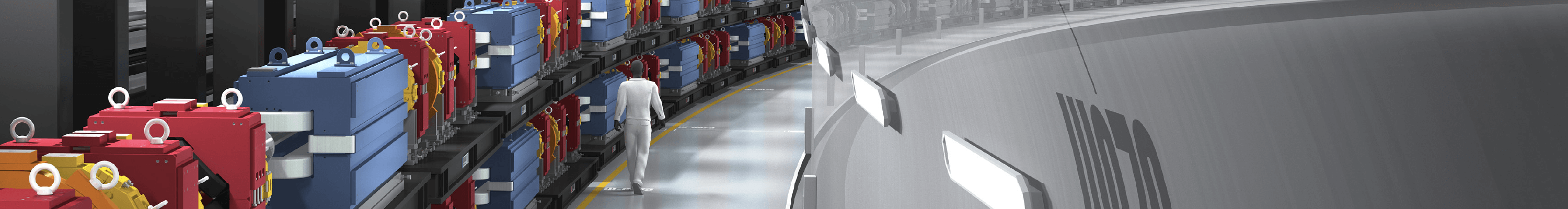

4 MAIN LINAC

Now comes the fast part. Up until this point, the electrons and positrons have been accelerated to a modest 15 GeV. The energy they need to reach at the collision point, however, is 125 GeV (or twice or even four times that at possible later phases of the ILC). At these energies, scientists hope they can see, and study in detail, the physics phenomena that have been out of reach or only been glimpsed at by other colliders.

Superconducting microwave cavities are the key to reaching this energy. The more accelerating voltage they can apply to the electrons and positrons, the shorter the accelerator can be (which can reduce the cost quite substantially). The cavities’ core quality is their acceleration gradient – the higher the gradient, the bigger the boost they can give to the particles. Gradients are however limited by the quality of the inner surface of the cavities, which must have an ultra-clean mirror-like finish as perfect as possible. Several decades of research on superconducting cavities have resulted in a recipe for fabrication and surface treatment that can produce cavities with a gradient exceeding the average 35 Megavolts per metre required for the ILC. 35 Megavolts per metre are needed for realising 31.5 Megavolts per metre after assembling the cavities into the cryomodules and installing them into the linac tunnel Despite this state-of-the-art performance, the two linacs still need to each be 6 kilometres long in order to accelerate the -particle bunches to 125 GeV per beam. -Operating at -271 degrees Centigrade, the ILC’s main linacs will also require one of the world’s largest liquid-helium refrigeration plants as similar as the one in operation at the LHC.

The electrons and positrons zoom through the cavities, accelerated along by the force of electromagnetism. An oscillating electric field inside the cavity at the frequency of radio waves – which is where the name of the acceleration technology comes from: superconducting radio-frequency acceleration – push the particles from cavity to cavity. For the beam energy of 125 GeV, they will pass through 4,000 cavities, or a total of 8,000 -cavities for both accelerators.

The production of these cavities and their surrounding equipment has been one of the greatest challenges in the R&D work for the ILC. Accelerator and particle physicists from institutes all over the world have worked in cooperation with industry from different countries to work out the best way to produce reliable as well as affordable cavities and their cryomodules, the containing structures within which they operate. The production of accelerator parts like cavities and cryomodules will be done by industry, certainly by different companies in different regions of the world, whose products then have to fit together to ultra-high precision.

Once accelerated through the main linacs, the positrons are ready for the final leg of the journey to collisions. However, the electrons have one additional job to do before colliding. We have not yet explained where the positrons come from – they are in fact produced by the electron beam!

5 POSITION SOURCE

While it is relatively straightforward to rip electrons out of a semiconductor with a laser beam, making positrons presents an altogether bigger challenge. This is because, unlike their matter counterparts the electrons, positrons do not actually exist naturally in our universe. They have to be produced.

The way the ILC will do this is by using the 125- GeV electron beam on its way to the collision point. The high-energy electrons will pass through a special magnet called a helical undulator string, which is more than 200 metres long. Just as in the damping rings, the electrons will be produced to radiate light in this magnet – indeed it is exactly the same phenomenon.

The difference is in the energy: the 125-GeV electron beam in the positron source’s helical undulator generates high-energy gamma rays in a very narrow cone. These gamma rays slam into a thin titanium-alloy target, knocking loose a shower of electrons and positrons. The accelerator sections downstream then collect the positrons and throw away the electrons. The positrons are then bunched, accelerated to 5 GeV and injected into the positron damping ring in much the same way as the electrons. In the meantime, the 125 GeV electron beam is gently bent away from the gamma ray cone and around the metal target before it proceeds on its way to meet the positrons generated on the previous machine pulse (every 200 millisecond) at the collision point.

An electron-driven design is an alternative to the TDR undulator concept for positron production. Although polarised positrons are not available in this scheme, positron beam commissioning is possible without a 125 GeV electron source. The e-driven source of positrons consists of a normal conducting (NC) 3 GeV linac, a positron target, and followed by a normal conducting 5-GeV linac.

6 FINAL FOCUS

When electrons and positrons have each reached their collision energy of 125 GeV per beam, the beams get one last massage before they enter the hall where it all happens: the interaction point around which the detector sits ready to record the collisions.

In the last two kilometres, instead of running through accelerating cavities the beams pass a series of specially designed and arranged magnets that ultimately focus them down to a height of just a few nanometres at the collision point. The “final focus” system can be thought of as a sort of microscope in reverse, where the beams are demagnified – instead of magnified – by a factor of about 300. Rather than using glass lenses as in an optical microscope, special arrangements of magnets are used to produce the focusing “lenses”.

The tiny beams need to be collided with an accuracy of a fraction of their size, so less than a nanometre! At this level, great care has to be taken to deal with vibration and other tiny fluctuations in magnetic and electric fields that can easily cause the bunches to wobble as they pass through the accelerator and final focus. Ultra-fast diagnostics systems analyse the shape and position of the bunches and tell the magnets how to correct them to optimise the collisions: without such fast “feedback systems”, the beams would simply miss each other. Using a purpose-built final-focus test beamline, ATF-II, hosted at KEK, an international collaboration has developed the controls and instrumentation needed to achieve these challenging parameters.

7 INTERACTION POINT AND DETECTORS

After all the squeezing, acceleration and focussing, the particles can finally hurtle towards their final destination: the collision between electron and its antiparticle, the positron. At full operation there are a potential 1.3 x 1014 (that’s 130 trillion) electrons and positrons per second, crammed into the tiny interaction area of just 7.7×515 nm2 – or just 0.000000004 mm2. Despite these impressive numbers, only a tiny fraction of the electrons and positrons actually collide. The higher the density of the particles at the interaction point, the greater the probability that some will collide: one reason why so much effort is made to produce tiny intense beams at the collision point.

When they do collide, electrons and positrons annihilate in a burst of energy, creating an array of new particles that fly out from the collision point. It’s these new particles, their interactions, lifetime, and energy that the detectors will study.

Arranged in concentric cylinders of subdetectors with different technologies and tasks, these detectors are awe-inspiring in speed and precision (and in physical volume). Years of research and development have already produced mature technologies and concepts which will be required for the unprecedented precision of the measurements that need to be made. This R&D will go on until the very last minute to get even better, faster results more cost-effectively. The way the detectors will take data is unique, too. Two detectors will be built as one has to verify the results of the other before physicists can claim to have made a discovery. In order to avoid building a second, very costly, final-focus system, the ILC scientists invented the push-pull system: while one detector is installed in the interaction point and takes data, the other is in servicing position. After some time they swap position, being moved on two gigantic platforms that ensures the stability of even the tiniest part within the huge detector.